Wrought iron

‘If a skill is not exercised it will be forgotten, and with it the ability to create in the manner of the past. The conservation of skills is perhaps just as important as the conservation of the artefacts.'

- Chris Topp, Blacksmith

By 1700, the Sussex Weald was Britain's biggest iron manufactury. Wrought iron is the purest form of the metal. The term ‘wrought' was used to describe the manufacturing process, because the iron was reheated and reworked a number of times to improve its strength. The greater the number of times the metal was reheated and reworked, the better the quality of the wrought iron produced.

Iron is extracted from iron ore by heating or ‘smelting’ using a carbon source such as charcoal, or with coke following the development of the Darby process in 1709. The carbon reacts with the oxygen to form carbon monoxide which is driven off as a gas, leaving impure ‘pig iron’, so called from the name of the rough bars into which it is cast. This could then be processed into cast iron, wrought iron, or steel, the latter being prohibitively expensive until the invention of the ‘Bessemer’ process in 1855.

Iron is extracted from iron ore by heating or ‘smelting’ using a carbon source such as charcoal, or with coke following the development of the Darby process in 1709. The carbon reacts with the oxygen to form carbon monoxide which is driven off as a gas, leaving impure ‘pig iron’, so called from the name of the rough bars into which it is cast. This could then be processed into cast iron, wrought iron, or steel, the latter being prohibitively expensive until the invention of the ‘Bessemer’ process in 1855.

Following the invention of cast iron in the late eighteenth century, the role of the blacksmith in the building industry began steadily to decline. Throughout the Regency, cast iron was used increasingly in both the construction and ornament of all manner of buildings. It was used in structural beams, columns, and staircases (instead of timber), and to make plates, shoes and bolts to strengthen timber roof, wall and floor structures. Ornamental railings, balustrades and stair balusters could be cheaply cast in complex designs and became very popular choices both for many prestigious buildings, including the upper and middle class houses in the Brunswick Town area.

Above: Regency cake basket styled iron balcony.

The material has succeeded as a building product for four reasons; its excellent behaviour under compression, the ease with which it can be cast to form decorative and structural pieces, its resistance to corrosion and, finally, its fire resistance due to its high melting point - 1200 C.

Traditionally, molten cast iron was poured into ‘green sand’ moulds, a damp sand and clay mixture able to hold a shape or pattern. Once cooled, the casting would be broken out and cleaned. Brighton builders had the good fortune to find themselves in one of the largest cast iron producing centres in Britain with founders such as George Packham & Son busily polluting the Trafalgar Street area of the town with black smoke and noxious fumes.

The manufacturing process for wrought irons saw pig iron smelted until it appeared to boil at which time the iron was worked vigorously or ‘puddled’, and carbon monoxide driven off until virtually no carbon was left. The more times the stiff iron mass was reheated and reworked, the better the quality of the wrought iron work produced.

Cast iron, in various forms, contains relatively high levels of carbon, sometimes as much as 5%. This ‘grey iron’ contains carbon or graphite flakes distributed throughout the metal causing weakness in the iron, whilst ‘white iron’ contains an iron carbide making the material harder and giving it superior tensile strength. However, cast iron’s crystalline structure makes both of these varieties relatively brittle and weak in tension.

Wrought iron has a fibrous structure and a low carbon content and is a much purer form of iron than cast and less prone to cracking. From the 18th century its greater tensile strength has been recognised and it was used extensively for structural beams and posts, as well as for decorative items such as latches and gates.Relatively expensive until 1820, the great days of wrought iron came in the middle of the 19th century where the tensile strength of the material was exploited in the building of railway bridges, viaducts and similar large-scale architectural engineering projects.

Also, individual craftsmen, such as wood carvers, would direct the blacksmith to make custom-designed tools, with very precise shapes, which they required for particular types of building work. Blacksmiths today have electrically driven coke fuelled forges, but the methods they are using to work the metal would be familiar to their Regency predecessors.

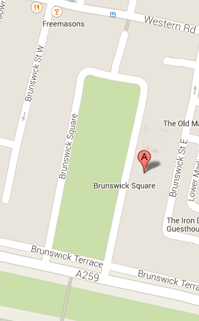

Above: Iron staricase railings at 13 Brunswick Square.

Today we can see wonderful examples of Regency iron columns and exquisite decorative screens which, with a little care and attention, will survive for another 200 years.

If you are interested in further reading on this topic, these links will provide you with more information:

'Brief History of Wrought Iron' by Ken Finnigan

Timeless wrought iron - The complete history

From ideas to drawings to buildings; Short history of wrought iron

Cast iron balconies and verandas on Freepedia