Carpentry and joinery

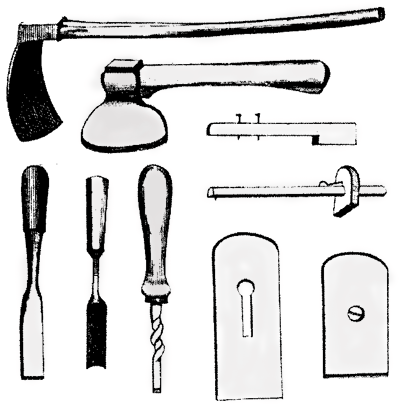

The carpenter does all the rough timber work necessary for support, division and connection within the structure.The carpenter uses a wide variety of tools, which include hammers, mallets, chisels, saws, planes, augers and gimlets.

Above: a carpenter's tools

During the late 18th century the British invented several pieces of automated woodworking machinery. These included the circular saw, by Samuel Miller, and a steam driven machine to bend wood for circular sashes, fanlights and handrails, by Samuel Bentham. By the early 19th century, men such as John Nash were acquiring interests in wood sawing and planing machines. However, it was the boom in urban development after the Nepoleonic Wars that saw these machines begin to impact significantly on timber preparation techniques.

Between 1822 and 1832 the number of saw mills in London alone more than doubled, while by 1837 two distinct categories of sawing machine were in use: the circular saw, for small pieces of timber; and the reciprocating or frame-saw, for larger beams. One reason for the rapid spread of saw mills was a general move away from the importation of preworked Baltic timber in favour of unworked American pine, which was cheaply available due to the relaxation of duties on colonial timber after 1815.

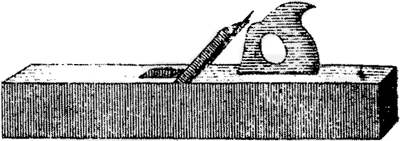

During the Regency the area around Shoreham would have seen the development of an industry based upon the conversion of wood into convenient sizes for the builder. Nevertheless, it is important to remember that at least some steps of the conversion process continued with conventional hand tools such as the hand saw, the adze and the finishing plane, right through the period.

Above: a wooden plane

As late as 1824, a Parliament Select Committee on Artisans and Machinery was declaring that the crafts of the carpenter, joiner, turner and carver were quite secure, although within 15 years such conclusions were unsound.

In 1825, the Brighton Commissioners contracted Lambert and Sons as carpenters and issued a printed specification, which today identifies some of the costs and types of wood then in common usage. Amongst these were, Swedish and Norwegian fir, Dantzic, Riga, and Memel fir, and English oak. The cost of Memel per cubed foot was 4 shillings and 8 pence (23.5 new pence) straight, and 7 shillings and 5 pence (37.5 new pence) carved, whilst English oak was one shilling straight, (5 new pence), and 10 shillings and 6 pence (52.5 new pence) carved.

Carpentry and joinery were the most common crafts in Regency construction. The carpenter produced the rough work necessary for support, division and connection within the structure. He used hammers, mallets, chisels, saws, planes, augers and gimlets. The joiner executed more detailed work. The joiner makes and fits all the fixed woodwork required for convenience or ornament, using tools very similar to those of the carpenter. The operations of the joiner include laying floors, boarding ceilings and wainscoting walls. He also produces window sashes, frames, doors and shutters; and moulded woodwork, such as architraves, skirting, panelling and picture and dado rails.

Carpentry and joinery were the most common crafts in Regency construction. The carpenter produced the rough work necessary for support, division and connection within the structure. He used hammers, mallets, chisels, saws, planes, augers and gimlets. The joiner executed more detailed work. The joiner makes and fits all the fixed woodwork required for convenience or ornament, using tools very similar to those of the carpenter. The operations of the joiner include laying floors, boarding ceilings and wainscoting walls. He also produces window sashes, frames, doors and shutters; and moulded woodwork, such as architraves, skirting, panelling and picture and dado rails.

If you are interested in further reading on this topic, these links will provide you with more information:

National heritage training group; Carpenter and joiner

Robert Carpenter's history of carpentry